Initial Production Check

Case Study - Unveiling Hidden Printing Errors: How Vigilant Quality Control Enhances Product Integrity

Product Inspection

In general, printed packaging and instructional materials for color boxes tend to have a relatively low probability of errors due to the use of pre-made printing plates and bulk printing. However, considering the extensive amount of text and pages involved in printing, issues often go unnoticed.

Nonetheless, in our daily quality inspection practice, we frequently encounter such problems. When errors of this nature arise, there are instances where we must replace all packaging boxes and instructional materials, potentially causing significant financial losses to our clients.

Below are some of the printing error cases we have come across:

Case One: Involving a baby chair product, the manufacturing factory is highly specialized and belongs to a large conglomerate with thousands of employees. During the inspection process, we meticulously examined dozens of pages of product manuals and identified a printed ant pattern on the second page. Upon verification, we confirmed that this ant was not an actual physical presence but a pattern generated during printing (photo1). Further examination revealed the same issue on other product manuals. Our analysis suggests that a real ant might have inadvertently found its way onto the printing plate at the factory, leaving this trace on the entire batch of manuals. To ensure product quality, the factory needed to unpack and replace all the manuals.

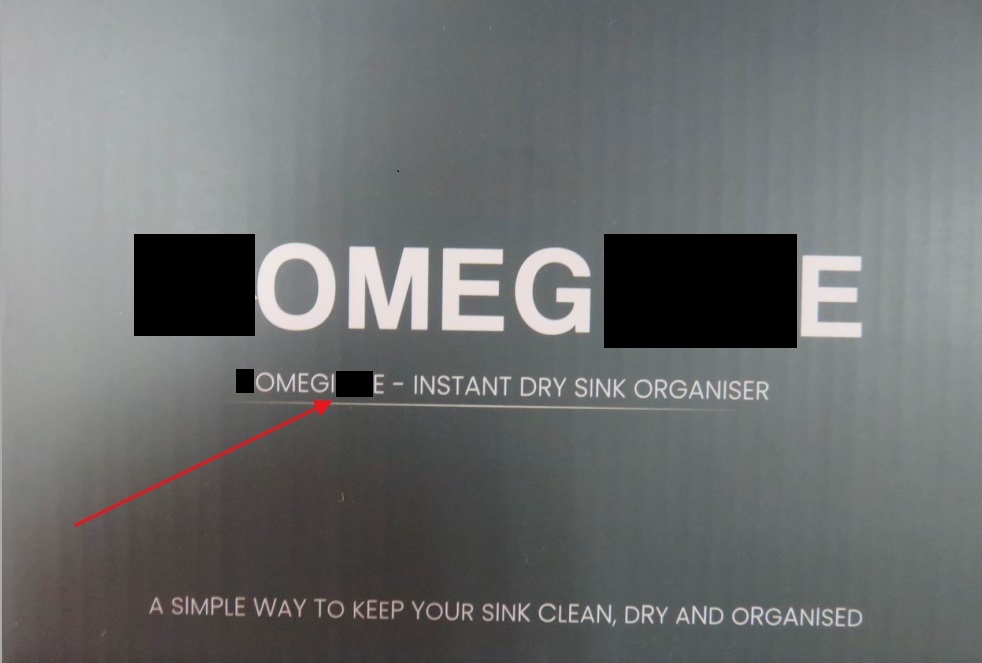

Case Two: Despite the absence of design materials for the color box packaging from the client, our quality control inspectors still diligently verify the accuracy of word spellings. During one inspection, we discovered that the word "*OMEGI***E" below had an extra letter "I" compared to the word above, which was clearly inconsistent (photo2).

In reality, prior to the printing of color box packaging, there are typically multiple confirmation processes at the client's factory to ensure the accuracy of the print content. However, surprisingly, this error remained unnoticed. We are pleased to have resolved such issues for our clients at this stage, reducing their inconvenience and concerns.

- Quality Control Inspection Services

- Quality Control Audit

- The Role of Product Inspection in Maintaining Quality

- Case Study - Decisive Differences in Barcodes and Model Numbers

- Case Study - Scrutinizing a Scratched Situation during inspection

- Case Study - Mold on Nail Files found from the product inspection

- Case Study - Discrepancies in Pet Water Dispensers

- Case Study - Attention to Detail - Snap Button Issue in Skiwear Accessories