Initial Production Check

Initial Production Check

As a manufacturer, upholding high-quality standards for your products should be a top priority -

especially when production is overseas. Performing rigorous quality checks along every step of

the manufacturing process is key to preventing issues down the line. This is where Initial

Production Check (IPC) services prove invaluable.

Read on to learn how partnering with quality control specialists like Hong Kong Q.C. Center in

Vietnam and China for comprehensive IPC can help you confidently maintain quality from the

early stages of manufacturing onwards.

What exactly is an Initial Production Check?

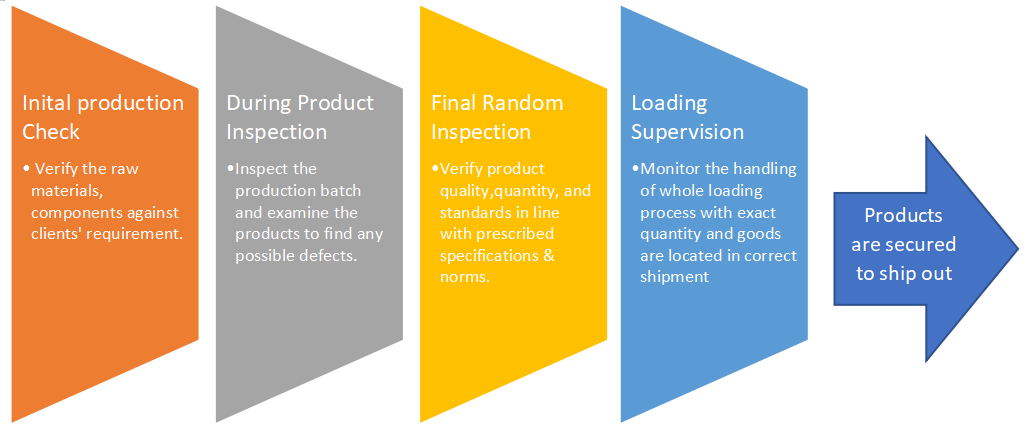

An Initial Production Check included under China product inspection services refers to a

thorough, in-depth inspection conducted at the start of the manufacturing process before full

mass production kicks off.

The key aim of an IPC is to verify the correct selection of all raw materials and components the

factory will use, ensuring conformity with specifications and quality requirements from the get-

go. Essentially, an IPC

Why is Performing an IPC So Critical?

While extensive planning and preparations may be made ahead of manufacturing, problems

can still slip through the cracks once production is underway. An IPC serves as a vital

preventative measure - catching any potential defects in materials, components, or methods

early on before they snowball into major quality issues down the line that impact entire

shipments.

By identifying non-conformities early in the trial production stages, you can address them

promptly and stay on track. An IPC, a part of China's product inspection service, establishes

quality control from day one.

The Key Advantages You Gain

Performing an Initial Production Check offers several tangible benefits:

- Detect Quality Issues Early: An IPC allows you to pinpoint any flaws in the manufacturing process while still early on in production when they are easiest to correct. This prevents small problems from escalating.

- Proactively Control Quality: Conducting an IPC enables you to front-load quality control measures, actively managing product excellence from the raw materials stage through the production process itself.

- Prevent Costly Delays: Catching issues early prevents quality problems further down the production line - saving you time, money, and inventory losses from shipment delays or rejections.

Partner with Quality Control Specialists

For manufacturers producing goods overseas in Vietnam and China, working with seasoned

quality control partners like us is advised for IPC services. Our team thoroughly inspects trial

runs and components during this vital first check, helping ensure your products consistently

meet rigorous quality criteria.

With years of experience in the industry, Hong Kong Q.C. Centers experts identify non-

conformities early for clients, delivering peace of mind.

Contact Hong Kong Q.C. Center Today

Ready to schedule a comprehensive Initial Production Check and uphold supreme quality for your next manufacturing run? Connect with the professionals at Hong Kong Q.C. Center today. Our IPC services enable you to proactively verify quality from step one.